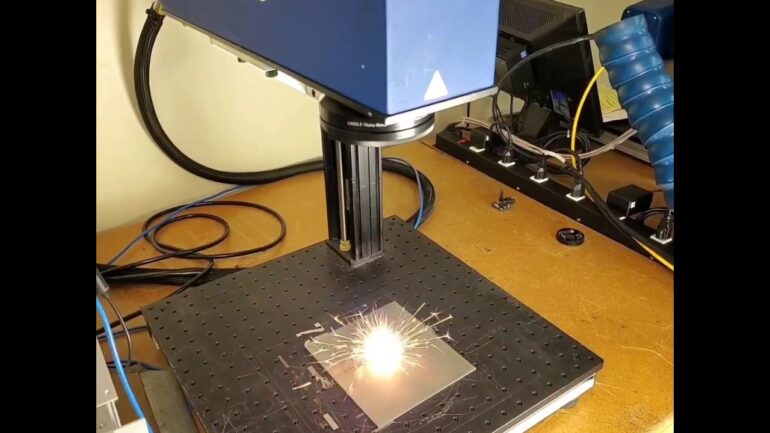

When it comes to marking, cutting, or engraving surfaces, laser technology is always the optimal choice. It is fast, efficient, and accurate. If you have the right type of laser, you can easily cut into almost any material and add whatever kind of text, image, or pattern you want. The benefits over traditional cutting are obvious and for anyone that plans on getting into this kind of work, a fiber laser marking machine is a must-have. Over the past several years, or more specifically this last decade, the technology of laser engraving machines has improved considerably.

What once used to cost tens of thousands of dollars, today it costs no more than $1000. It really is incredible how far this technology has reached. However, anyone that is not familiar with this technology will have a very difficult time buying the right machine. There are so many different features, benefits, and disadvantages that you will need to look at before you can make the purchase. To help you with that, I decided to write this article and tell you about all the things you need to know before you can buy a fiber laser marking machine.

Proper optical lens care

One of the most important parts or maybe the most important part of a fiber laser marking sheen is the optics. Without the lens, the laser beam cannot be strong enough to cut into any material. With the help of these optical parts, into one tiny spot, allowing you to engrave, cut, and mark. Think of it as focusing all of the power from the machine in just a few millimeters.

However, the problem with the optical lens is that they are very fragile. One drop could make it shattered and even just one scratch could make it completely useless. In other words, this is a very vulnerable part that you must take care of. If the device needs maintenance, you have to carefully take it apart to ensure that you do not scratch or damage the lenses. Once you successfully remove them, make sure you put them in a safe place, preferably covered with a microfiber cloth.

Using anything different than microfiber can easily scratch the surface of the optics. Not recommended. Also, you should avoid leaving the optics out in the open. Believe it or not but even dust and other small particles can damage it. It is also recommended to avoid touching the glass directly with your fingers. Your fingers have oil, grease, and all kinds of other contaminants that could be the cause of future damage.

Proper training is required

It is true that fiber lazing marking machines are now more accessible than ever. You can even buy one from Amazon for less than $200. Of course, that $200 machine will not be in any way similar to one that costs several thousand dollars, but at least it exists on the market. However, just because this technology is now accessible to the average customer that does not mean that you should use one without proper training.

Fortunately, certain manufacturers or companies will provide you with details on safety, maintenance, techniques, and all kinds of other operation principles on your brand-new fiber laser marking machine. For more information, check out https://hispeedlaser.com/fiber-laser-marking-machine/. With this kind of training, you will certainly be able to handle the device safely. You will know exactly what you should and should not do. Because if you do not, not only do you pose a danger to yourself and to your coworkers, but you also be a danger to the finished product.

Installation

The first time you order this kind of device, you will need a bit of guidance to set it up. The installation process is not simple nor easy. Fortunately, as mentioned previously, the manufacturers should provide you with a guide for the installation process and all the safety procedures that you will need to follow. Equally important is where the machine will be located. It needs to be a room with very low humidity and clean. Like I mentioned previously, even the smallest specs of dust can damage certain parts. It is vital to keep the surrounding area clean.

Always check settings before use

One of the largest expenses of using this kind of device is the materials. The more materials you need, the more money you will spend. To effectively reduce your expenses as much as possible, it is essential to always check the settings of the device before use. Even when you are certain that the settings have not been altered, it is good to have that kind of habit. Who knows might have happened. Someone could have altered the parameters without telling you. Or, maybe the machine itself has reset settings.

Regular maintenance

Usually, fiber laser marking machines are very durable and require little maintenance over the years. But, if you want to make sure that this machine lasts as long as possible, you will need to do some regular maintenance. For basic and regular maintenance, it is often best to resort to the user’s guide or manual. If the manual is not informative enough on this topic, you can always contact the manufacturers to provide you with some guidance.

Always do a test run first

This is another one of those essential things that you need to know before you can use your fiber laser marking machine. This tip will also help you save on unnecessary expenses. Whatever kind of product you are working on, it is always better to do a test run first to ensure that you input the right parameters. The test run should be done on a disposable object that is of similar material. By doing this, you will not be actually wasting any of the expensive material. There are probably a lot of other things you will learn as you use your laser engraving machine, but these things I mentioned above are some of the essential things is simply have to know.