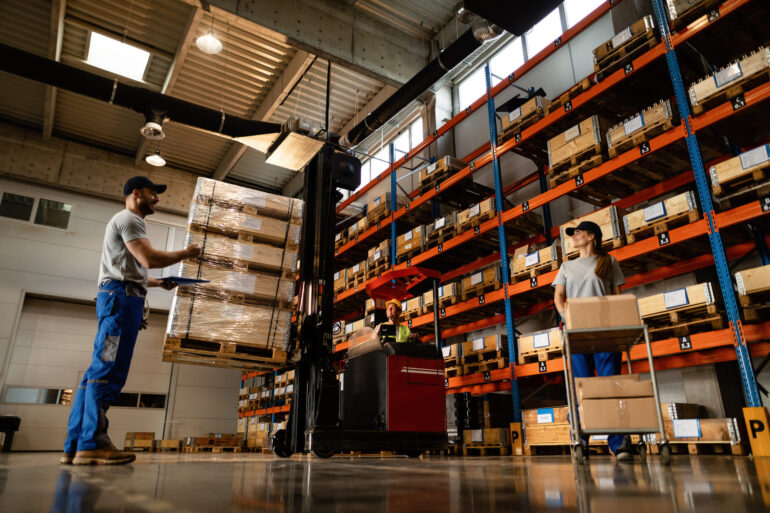

In the fast-paced world of logistics and supply chain management, efficient warehouse receiving is paramount. It’s the crucial first step in a warehouse’s operations, setting the foundation for inventory management and order fulfillment.

Despite its importance, many businesses struggle with optimizing this process. A potential solution lies in leveraging the expertise of third-party logistics companies, like Shipro, to refine and improve receiving practices.

Understanding Warehouse Receiving

Definition and Importance

Warehouse receiving is more than just accepting goods; it’s a detailed process involving the inspection, documentation, and storage of incoming merchandise. This stage is critical as it affects everything from inventory accuracy to customer satisfaction.

According to a study by the American Productivity & Quality Center, businesses with optimized receiving processes see a 25% increase in inventory accuracy.

Cost Implications

The financial implications of efficient receiving are significant. Research indicates that businesses can save up to 20% of their operational costs by streamlining receiving processes. These savings stem from reduced labor costs, minimized errors, and lower inventory holding costs.

For example, a study in the International Journal of Logistics Management showed that companies that invested in receiving efficiency reduced their warehousing costs by an average of 18%.

Impact on Customer Satisfaction

There’s a direct correlation between receiving efficiency and customer satisfaction. Efficient receiving ensures that products are available when needed, thereby reducing lead times and improving order accuracy.

A report by the National Retail Federation highlighted that retailers who improved their receiving efficiency saw a 25% increase in customer satisfaction scores, mainly due to better on-time delivery and product availability.

Sustainability and Environmental Benefits

Optimizing receiving processes also contributes to environmental sustainability. Efficient receiving reduces the need for excess storage space and lowers energy consumption.

According to the Environmental Protection Agency, logistics companies that focused on improving receiving efficiency reported a 10% reduction in their carbon footprint, thanks to fewer transportation needs and lower energy usage in warehouses.

The strategic importance of warehouse receiving extends beyond the warehouse itself. Its optimization is a key driver for operational efficiency, cost reduction, customer satisfaction, and environmental sustainability.

As businesses continue to navigate a competitive and fast-changing market, focusing on refining the receiving process becomes not just beneficial, but essential for long-term success.

The Core Elements

The process can be broken down into several core elements:

- Arrival of Goods: The process begins with the delivery of items to the warehouse.

- Inspection and Verification: Items are inspected for quality and checked against purchase orders.

- Documentation: All goods are meticulously recorded, often digitally.

- Storage and Organization: Following inspection, items are stored in their designated locations.

Common Challenges in Warehouse Receiving

Many businesses encounter hurdles in warehouse receiving, which can include:

- Inaccurate Record-Keeping: Errors in documentation lead to inventory discrepancies.

- Inefficient Sorting and Storage: Poorly organized goods can slow down the entire supply chain.

- Limited Space and Resources: Constraints in space and manpower can lead to congestion and delays.

- Inadequate Technology Integration: Reliance on outdated methods can hamper efficiency.

Standardizing the Receiving Process

Best Practices

Implementing best practices is crucial for an efficient receiving process:

- Clear Procedures: Establishing and adhering to standard operating procedures ensures consistency and accuracy.

- Adequate Staff Training: Regular training sessions keep the staff updated on best practices and technologies.

- Quality Control: Implementing stringent quality control measures prevents future inventory issues.

The Role of Technology

Technology plays a pivotal role in streamlining the receiving process:

- Digital Inventory Tracking: Tools like barcodes and RFID systems enhance accuracy in tracking.

- Warehouse Management Systems (WMS): These systems offer comprehensive solutions for inventory management, data analysis, and process automation. Implementing a WMS can reduce order fulfillment errors by up to 35%, as reported in a study by Logistics Management.

Leveraging Third-Party Logistics Expertise

The Benefits of Partnering with Companies

Third-party logistics companies, offer specialized expertise and resources that can significantly enhance warehouse receiving:

- Advanced Technology Solutions: Access to state-of-the-art technology for inventory management and process automation.

- Expertise and Experience: Benefit from the extensive knowledge and experience of a dedicated logistics partner.

- Scalability and Flexibility: Ability to scale operations up or down based on business needs.

Integration of Third-Party Services

Integrating services provided by a third-party logistics company involves:

- Collaborative Planning: Working together to develop a tailored logistics strategy.

- Technology Integration: Seamlessly integrating third-party systems with existing warehouse infrastructure.

- Continuous Improvement: Regularly reviewing processes and making adjustments for ongoing optimization.

Case Studies and Success Stories

Highlighting a few success stories can illustrate the impact of effective warehouse receiving:

- Company A: After integrating a WMS and partnering with 3PL service providers, Company A saw a 30% reduction in inventory inaccuracies.

- Company B: By standardizing its receiving processes and training staff, Company B improved its throughput time by 25%.

Future Trends in Warehouse Receiving

Looking ahead, several trends are likely to shape the future of warehouse receiving:

- Automation and Robotics: The increasing use of automation and robotics for tasks like sorting and storing goods. Expected to reduce manual labor in warehouses by up to 65% in the next decade.

- AI and Machine Learning: Advanced AI can predict inventory needs and optimize receiving schedules.

- Sustainability Practices: More focus on eco-friendly practices in logistics, from packaging to transportation.

Conclusion

Effective warehouse receiving is a critical component of a streamlined supply chain. By understanding its importance, overcoming common challenges, and leveraging the expertise of third-party logistics companies, businesses can achieve significant improvements in efficiency and accuracy.

The integration of technology, adherence to best practices, and a commitment to continuous improvement will ensure that warehouse receiving remains a strong link in the supply chain ecosystem.