Alloy steel casting is a vital process in modern manufacturing. It’s how we get those tough, precise components for industries like aerospace, automotive, and even the tools we use every day. But let’s be real: casting isn’t all sunshine and perfect molds. It’s tricky, messy, and sometimes downright infuriating.

Let’s dive into the challenges without any fluff and get straight to what you’re here for: real talk and real solutions.

Key Points:

- Impurities are a major headache.

- Shrinkage can ruin everything.

- Porosity messes with the material’s strength.

- Warping makes parts unusable.

- Temperature control is critical.

1. Impurities: The Unwanted Guests

Think of impurities as the freeloaders at your party. They show up uninvited and ruin the vibe. In casting, these can be things like non-metallic inclusions or chemical contamination. Impurities weaken the final product and lead to rejection.

How to Kick Them Out:

- Use high-quality raw materials.

- Filter molten metal to trap unwanted elements.

- Keep the workspace clean to avoid contamination.

Pro tip: Inspect materials thoroughly before using them. A little prevention saves a lot of headaches later.

2. Shrinkage: The Sneaky Saboteur

When molten metal cools, it contracts. Shrinkage causes cracks, voids, or dimensional inaccuracies. Imagine baking a cake and watching it collapse in the middle—that’s what shrinkage feels like.

Combat Shrinkage with These Tips:

- Use chills to direct solidification.

- Design molds with proper risers to feed molten metal during cooling.

- Avoid overcomplicated designs that trap heat.

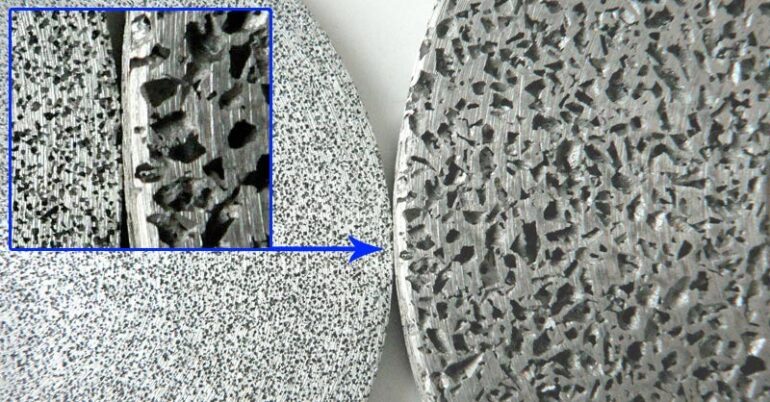

3. Porosity: Swiss Cheese Syndrome

Nobody wants a casting that looks or behaves like Swiss cheese. Porosity reduces strength, and that’s a dealbreaker for many applications. It happens when gas gets trapped or metal cools unevenly.

Fix It Like a Pro:

- De-gas the molten metal before pouring.

- Optimize pouring techniques to minimize turbulence.

- Ensure molds are vented properly to let gases escape.

4. Warping: When Things Go Sideways

Warping isn’t just annoying; it’s expensive. Parts that don’t fit specifications go straight to the scrap bin. Uneven cooling or residual stress is usually the culprit.

Stay Straight with These Steps:

- Use uniform cooling methods.

- Control the rate of cooling with proper insulation.

- Avoid sharp transitions in mold designs.

5. Temperature Control: The Balancing Act

Temperature can make or break your casting. Too hot, and you risk defects. Too cold, and you’re dealing with incomplete fills.

Nail the Temperature Game:

- Preheat molds to prevent sudden cooling.

- Monitor temperatures closely with reliable sensors.

- Use consistent melting techniques to avoid fluctuations.

Benefits of Alloy Steel Castings

When everything goes right, you get to enjoy the perks. Curious about the full list of advantages? There are a lot of them which make them a popular choice across various industries. Here’s an expanded look at the benefits of alloy steel castings:

- Enhanced Durability: Alloy steel castings are known for their exceptional strength and resilience, making them ideal for high-stress applications. They can withstand wear, impact, and extreme conditions without compromising performance.

- Versatility: With a variety of alloy combinations available, these castings can be tailored to meet specific requirements such as resistance to corrosion, heat, or abrasion. This makes them suitable for industries ranging from automotive to construction and beyond.

- Cost-Efficiency: While the initial cost might be higher compared to some materials, alloy steel castings offer excellent long-term value due to their longevity and minimal maintenance needs. Their reliability often reduces the overall lifecycle cost.

- Improved Mechanical Properties: By incorporating different alloying elements like chromium, nickel, or molybdenum, the mechanical properties of the steel can be enhanced, such as tensile strength, hardness, and ductility.

- Heat Resistance: Certain alloy steel castings are specifically designed to perform well under high temperatures, making them indispensable for applications like turbines, boilers, and exhaust systems.

- Corrosion Resistance: Depending on the alloy composition, these castings can resist oxidation and corrosion, extending their lifespan even in harsh environments such as marine or chemical industries.

- Ease of Customization: Alloy steel can be easily molded and fabricated into complex shapes, allowing manufacturers to create components with intricate designs and precise specifications.

- Eco-Friendly Options: Many alloy steel castings are recyclable, contributing to sustainable manufacturing practices and reducing environmental impact.

These benefits make alloy steel castings a smart and versatile choice, enabling industries to meet demanding requirements with confidence.

Common Casting Challenges in a Nutshell:

Here’s a quick list of other pesky issues:

- Surface Finish: Rough surfaces need extra machining. Use better molds.

- Hot Tearing: This happens when the metal’s strength fails during cooling. Adjust cooling rates.

- Dimensional Tolerance Issues: Always double-check mold dimensions.

FAQs About Casting Challenges:

Q: How do I avoid hot spots in my molds?

A: Use chills or change the mold design to promote even cooling.

Q: What’s the best way to detect defects early?

A: Non-destructive testing methods like X-rays or ultrasonic testing work wonders.

Q: Why does my casting crack during cooling?

A: Likely due to residual stress. Focus on gradual and uniform cooling.

Tips for Smooth Casting Operations:

- Always have a backup plan for unexpected issues.

- Document everything to track patterns and improve processes.

- Invest in quality equipment. Cheap tools cost more in the long run.

Closing Thoughts:

Casting is an art and a science. There’s no room for guesswork. When you nail the process, you unlock the true potential of alloy steel components. Follow these tips, tackle challenges head-on, and watch your casting quality improve. It’s a game of precision and patience, but the rewards are worth it.

Ready to up your casting game? Share your thoughts or tips in the comments. Let’s make casting challenges a thing of the past.