High-speed disperser mixers stand as indispensable assets across a spectrum of industries, serving as pivotal instruments in the pursuit of efficient and high-performance mixing processes.

Understanding the essence of these mixers is paramount for professionals spanning various domains, for they bestow a multitude of advantages, spanning from dispersion and homogenization to the reduction of particle size and the augmentation of reaction efficiency.

Understanding High-Speed Disperser Mixers

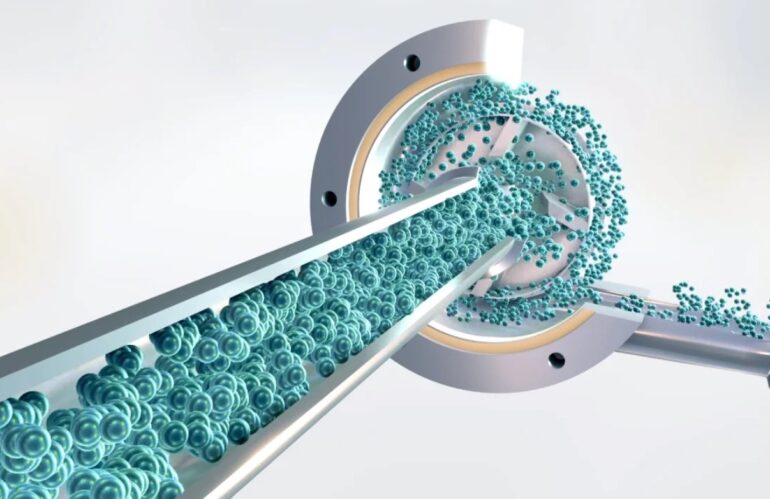

High-speed disperser mixers emerge as robust apparatus meticulously engineered to amalgamate, disseminate, and homogenize a wide spectrum of materials. These mixers comprise a motor-propelled shaft, adorned with an array of blades or impellers, which whirl at dizzying speeds within a vessel cradling the materials primed for amalgamation.

Their applications traverse an extensive gamut of industries, encompassing domains like paint manufacturing, pharmaceuticals, food production, cosmetics, and chemical processing.

The crux of high-speed disperser mixers’ significance resides in their capacity to orchestrate uniform amalgamation and dispersion of constituents, ushering forth products graced with unwavering quality.

Principal Functions of High-Speed Disperser Mixers

Function 1: Precision Dispersion of Solid and Liquid Phases

High-speed disperser mixers shine in their ability to disperse solid particles into liquid matrices with unparalleled efficiency. Industries such as paint manufacturing, pharmaceuticals, and adhesives hinge on this function to safeguard product quality.

In the realm of paints, it is not merely aesthetics at stake; the accuracy of color and paint performance hinges upon uniform pigment dispersion. In pharmaceuticals, where precision is paramount, these mixers ensure even distribution of active ingredients, upholding the efficacy and safety of medications.

Furthermore, in adhesive production, the dispersion of fillers and bonding agents is paramount in crafting adhesive compounds that confer robust and dependable bonds. In this vein, high-speed disperser mixers champion product integrity, curbing wastage, and elevating overall production efficiency across diverse industrial landscapes.

Function 2: Homogenization Par Excellence

High-speed disperser mixers assume an irreplaceable mantle in homogenizing mixtures, warranting the equitable distribution of all components. This function finds its zenith in industries like food production, where consistency in texture and flavor reign supreme.

For instance, in the dairy sector, homogenization ensures the inseparability of milk and cream, culminating in a silkier and creamier end product. In the world of cosmetics, the quest for uniformity in lotions, creams, and formulations transcends aesthetics, for it underpins product stability and efficacy.

Moreover, within the pharmaceutical domain, homogenization guarantees uniform dosages, bolstering patient safety and the efficacy of treatments. High-speed disperser mixers, with their artistry in bestowing uniformity through homogenization, emerge as invaluable allies spanning a panorama of sectors.

Function 3: Agglomerate Annihilation

Agglomerates, clusters of particles, wield the potential to disrupt manufacturing processes and imperil product quality. High-speed disperser mixers, with their alacrity in dismantling these clusters, champion a more even distribution of particles across diverse chemical processes.

For instance, in the chemical processing domain, the efficient dispersion of additives and reactants is pivotal for maintaining consistent chemical reactions and delivering premium end products.

By disintegrating agglomerates, these mixers infuse precision and dependability into chemical processes, yielding cost savings and elevating product quality to loftier heights.

Function 4: Meticulous Particle Size Reduction

Exacting control over particle size reduction constitutes another vital function etched into the DNA of high-speed disperser mixers. Whether the objective is to refine particle size for pharmaceutical powders or to craft fine emulsions in the food industry, these mixers proffer a level of control that proves indispensable in meeting precise product specifications.

In pharmaceuticals, for instance, attaining the desired particle size ranks as a linchpin for drug efficacy and patient safety.

In the food sector, ensuring uniform particle sizes in products such as sauces, dressings, and beverages lays the foundation for a consistent sensory experience for consumers. High-speed disperser mixers confer the power to tailor particle size reduction with surgical precision, ensuring products adhere to the most exacting standards of quality and performance.

Function 5: Augmenting Reaction Efficiency

High-speed disperser mixers embrace a pivotal role in heightening the efficiency of chemical reactions. By orchestrating more thorough mixing and dispersion of reactants, these mixers pave the way for reactions that are not only more comprehensive but also swifter in execution.

In the chemical industry, optimizing reaction efficiency transcends the realm of product yield; it encompasses the domains of energy conservation and waste minimization.

Illuminating case studies and instances from the chemical industry extol the contributions of high-speed disperser mixers in fortifying various chemical processes, underscoring their centrality in championing efficient and sustainable production methodologies.

By optimizing the utilization of reactants and curbing the generation of undesirable by-products, these mixers forge a pathway toward both economic and environmental sustainability.

Factors That Shape High-Speed Disperser Mixer Functions

Equipment Design

The design of high-speed disperser mixers exercises an overarching influence on their functions. The interplay of blade configurations, vessel design, and impeller positioning charts the course for mixing efficiency.

We shall embark on a journey through the diverse design elements, delving into their impact on performance, and elucidating the merits of various designs within specific applications.

Speed and Agitation Control

The capacity for precise control over the speed and agitation levels of high-speed disperser mixers stands as a linchpin for attaining optimal results.

We shall embark on a voyage through the realm of adjusting these parameters, unraveling their role in the mixing process, and articulating the significance of maintaining unwavering control to orchestrate uniform dispersion and homogenization.

Material Properties

The properties underpinning the materials to be mixed, spanning viscosity, shear characteristics, and compatibility, hold the sway to either fortify or challenge the mixing process. Our journey will usher us into a realm where these properties emerge as protagonists, shaping the dynamics of the mixing process, and proffering insights into surmounting potential challenges.

Optimal Practices for the Pinnacle of High-Speed Disperser Mixer Functions

Maintenance and Cleaning

Regular maintenance regimens and meticulous cleaning routines emerge as imperatives for extending the lifespan of high-speed disperser mixers and sustaining their performance zenith. We shall proffer pragmatic insights and guidelines for the upkeep of these machines, translating into cost savings and the elongation of equipment life.

Safety Considerations

The operation of high-speed disperser mixers demands strict adherence to safety protocols, safeguarding both personnel and equipment. We shall cast a spotlight on essential safety precautions, underscoring the paramount importance of donning protective gear and adhering to industry best practices.

In summation, high-speed disperser mixers stand as versatile and irreplaceable instruments across an array of industries, ushering forth functions encompassing dispersion, homogenization, agglomerate dismantling, particle size reduction, and the augmentation of reaction efficiency.

To apprehend the crux of these functions, along with the factors that mold their performance and the optimal practices to harness their full potential, assumes paramount significance in the pursuit of processing efficiency and the preservation of product excellence.

As industries continue their relentless evolution, high-speed disperser mixers shall maintain their vanguard position in the realm of innovation, catalyzing the ascent of product quality and the augmentation of productivity.

Professionals traversing a diverse spectrum of sectors are entreated to embark on a voyage of deeper exploration into these functions, unraveling the full tapestry of possibilities that high-speed disperser mixers unfurl within their operational landscapes.