Ever since wood became a necessary raw material for human society, in addition to firewood and weapons, for the construction of housing, later buildings, and other products for various purposes, the forest has become an inexhaustible natural source of wealth and raw materials. One of the basic problems that arose was the extraction or transport of the fallen log from the forest to the workshop or construction site.

In the exploitation of forests, mechanization is becoming more and more important every day. Timber attachments and grabs belong to the group of construction machines, and are used for pulling fallen trees and finished logs out of inaccessible forest terrain easily an accessible path or warehouse from where logs can be easily further transported by conventional means mode of transport. For this purpose, it is equipped with devices and tools for receiving and towing, or carrying logs.

There are three methods of attracting wood:

- traction on the ground (livestock, adapted agricultural tractor or skidder),

- export on wheels (tractor set – crew or forwarder) and

- taking out (forest cable car or helicopter).

Development mechanization and work technique, the process of obtaining wood is faster and raises worker safety to the highest possible level. In any case, foresters usually choose the first way because it is the easiest. If you are considering whether you need a machine like this, then read a few things about it that will help you to make a choice.

1. 4×4 drive

Due to the inaccessible terrain, timber grabs have four-wheel drive, and unlike classic tractors where the front wheels are smaller, these machines have four equal wheels. When pulling wood, the raised end of the load rests on the rear of the skidder and the dynamic loads of the front and rear axles are equalized or, depending on the position of the wood in the load, the size of the load and the slope, the loads on the rear axle are higher.

The limit load that the skidder will be able to attract is therefore determined by the permissible rear axle load, the longitudinal stability angle, and the realization of the traction force over the wheels.

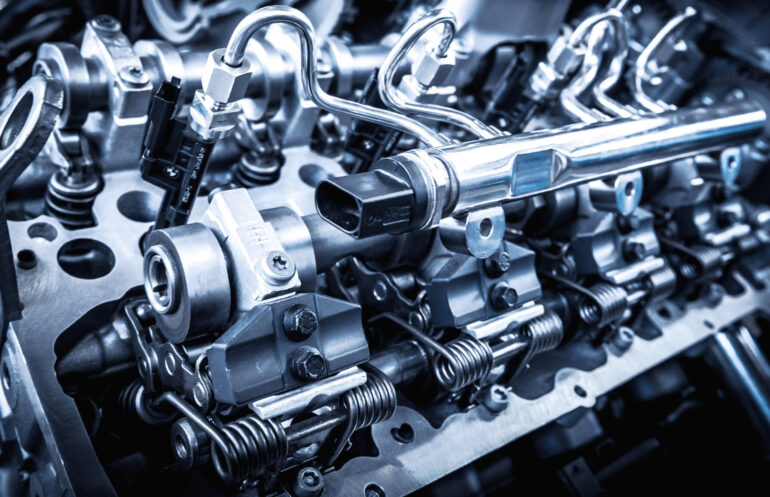

2. Engine

The propulsion part consists of an internal combustion engine, most often a four-stroke diesel engine. The transmission system transmits power from the engine to all wheels. The goal of the power transmission system is to increase the torque achieved on the wheel. By studying the current development and production of these in the world, it is concluded that most timber grabs and other similar machines use a mechanical transmission. The transmission system consists of a clutch, gearbox, drive distributor, differential on each axle, and a planetary or end gear on each wheel.

3. Technical characteristics

The weight of the logs for pulling out and transporting logs is approximately 7 tons (60% is on the front axle and 40% on the rear axle). Timber grabs are becoming more and more massive, and the reasons are in the demands for increase productivity and their application and durability. The transmission is usually with 5 forward and 1 reverse gear with a fast and slow gear.

Although log handles are made of durable materials, they sometimes break. Even if it happens, don’t worry, it can be replaced. This is very useful to know because on one machine you can change the grips as needed. Read more about it at uniforest.de.

4. Work techniques

The movement of machines in the forest is allowed only on pre-marked or built forest roads. Adjacent trees along the road need to be adequately protected from damage. Machinery should be operated in such a way that adjacent trees are not damaged. The weight of the load and the load capacity of the terrain must always be taken into account. Overloading leads to excessive soil compaction and also damages the veins and roots of the surrounding trees.

The removal of wood is primarily related to inaccessible hilly and mountainous areas, where due to large height differences at short horizontal distances, the construction of forest roads is costly and environmentally unacceptable. When taking out the wood, the roundwood is completely or partially lifted from the ground, which does less damage to the soil and young growth along the route of the cable car and is as such an environmentally suitable procedure.

5. Safety when working with forest machines

During the attraction of wood assortments, workers and other persons must not be on the towing line or drive with the driver, on the tractor, or on the wood assortments that are being attracted. In order to prevent hazards in group work, the driver of the machine must not start attracting wood assortments until the assistant gives them the contracted start signal. The worker who manages the mechanized means must be trained to attract logs, roundwood, and other wood assortments.

Under adverse weather conditions (rain, wind, snow, cold, etc.) the attraction of wood assortments can only be done with a machine that has a safety cab with a driver’s seat. The tractor with the cab must be able to be easily mounted or removed from the cab. The tractor cab must be designed to protect the driver or front passenger if two seats are installed in the cab, from bad weather, falling and hanging branches, roundwood bumps, and other objects, injuries in the event of a tractor overturning, etc.

Final thoughts

Today’s forestry can in no way be compared to forestry from the beginning of the last century. World forestry is based on short patrol forests, forest plantations, and crops in which clean felling is carried out and high – tech mechanization, such as which is an example of joint work: harvester – forwarder where they combine work felling and making wood and exporting assortments from felling.

Due to the extreme risk when working with machines on forest terrains, it is important to strictly control the correctness of the timber grabs and maintain them properly. Although evolving mechanization improved and accelerated the work of obtaining wood, it is still a human factor necessary for proper forest exploitation. That is why it is extremely important to educate workers and to promote and respect the norms of safety and protection of workers engaged in forestry affairs.