The desire to invent and create machines that will replace humans in their jobs that are too dangerous, tiring, or monotonous, has probably been present in human minds forever.

Very often, constructions of these machines took on a human-like appearance, partly due to the desire to make one’s own replica, and partly due to the easy fitting of a machine conceived in this way to a workplace that is already adapted to humans.

Although during recent history one can find examples of complex mechanisms that realized very complex movements, these devices, at the interpretation, they cannot be called robots.

First of all, robots are expected to perform a much wider range of activities than these automatons could realize, i.e. they are expected to be able to perform various tasks, and intuitively, the robot is expected to act independently and purposefully in the environment in which it is located.

There were no conditions for the realization of such machines at that time. However, thanks to solutions like linear motion by Tuli, things have slightly changed. We are now in the era of mobile and linear robotics, or in other words smart robotics.

What are linear slides?

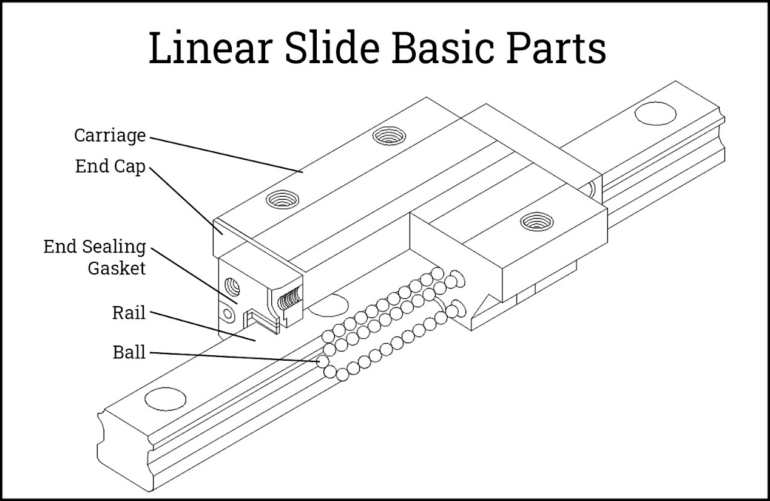

They are an essential element of many machines including robots, but also of various other assemblies such as furniture. Their basic role is to move parts of a system in the desired direction in the most functional way, with as little resistance as possible, with the help of linear rail and blocks.

As an integral part of machines, they ensure that the moving parts in the machine move along a specific path and in an appropriate manner, all with the help of external force.

Different types for different purposes

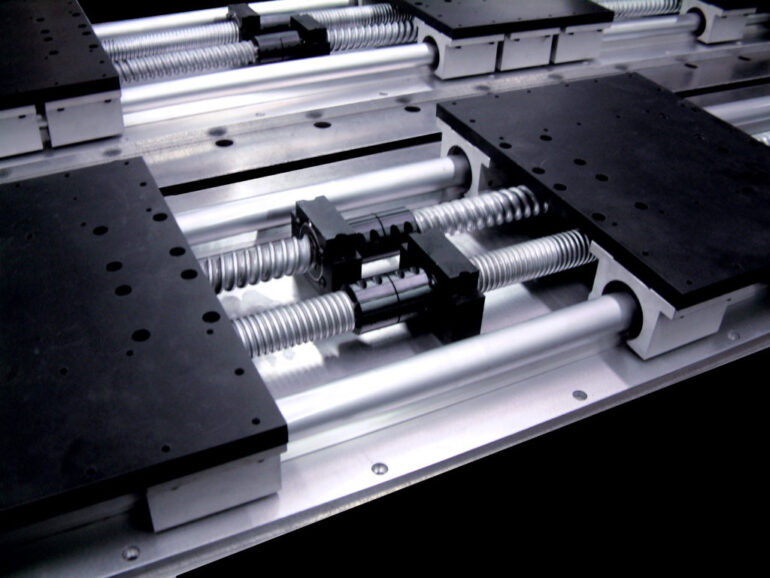

Linear slides are an essential building element of many machines, devices, and assemblies, and have always been an important link in their production, but often unfairly neglected. But their production has progressed a lot, so you can choose from a wide range of slides from various manufacturers and prices.

Given that they are extremely important for the harmonious functioning of machines and similar devices, they have played a very important role in the advancement of robotics and automation processes.

As in the above case, there are linear slides of various types and purposes on the market, and the most popular are linear ball splines, which are used the most in the industry, considering that they have a great possibility of adjustment.

One of the most important factors when choosing linear slides is their ability to bear loads. Those bearings where the load is evenly distributed along all points of movement will have their maximum effect. That is why it is important to know their specifications and choose the ideal linear slides for that purpose. You should also be informed about whether the bearings are of the open or closed type, as this also affects their load.

The linear shafts on which the slides are located can be made of different materials and this is how linear bearings differ from others – they can use different shafts. The most common material for making is steel, which has shown the best performance during operation.

All this technology has led us to the point where we can use smart, mobile robots for different purposes.

What makes a linear robot smart?

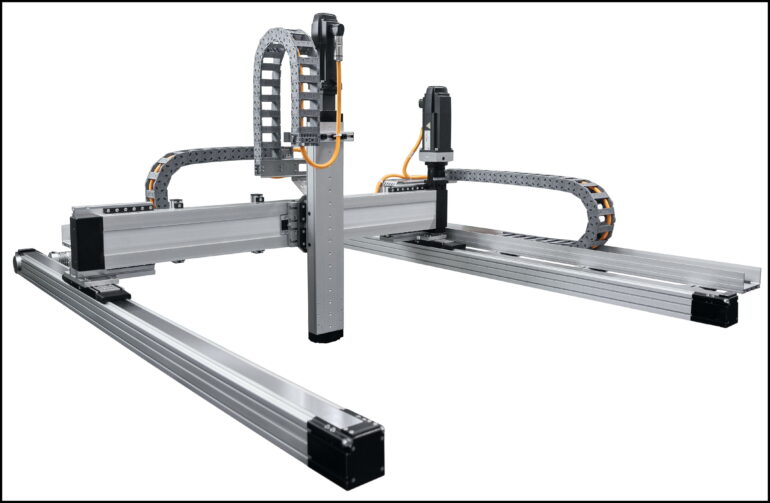

Linear manipulation robots are not new. They are well-known as Cartesian coordinate robots, gantry robots, gantry systems, or linear multi-axis systems. What is really new is the fact that they no longer need to be painstakingly assembled and programmed by programmers using linear axes, motors, drive controllers, and a control system.

Instead, they are available as ready-to-install “plug and play solutions” that can be easily configured and commissioned as part of a software-driven, intuitive process – just like a notebook computer that is configured online and delivered ready to use.

What about mobile robots?

Mobile robots represent a branch of robotics where robots can move independently in space, unlike traditional robotics, where the robot’s working area is limited.

This basic feature of mobile robots enables them to be used in many different areas of application, for example in supply chains, the entertainment industry, the military industry, rescue missions, exploration of our planet, but also space exploration.

The movement of mobile robots can be realized in several ways. Some of the most common are walking, bouncing, sliding, and rolling. All of this, thanks to linear slides and ball splines.

About robotics…

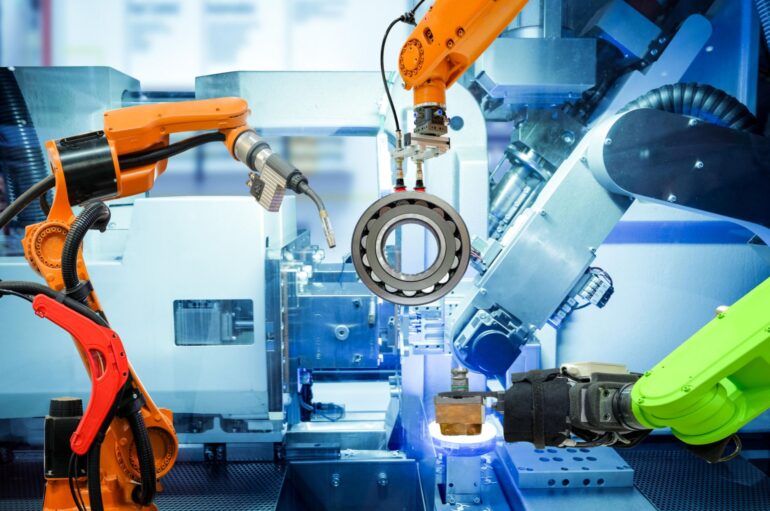

While in the initial stages, the development was mainly focused on industrial robotics, the contemporary moment and the recent past are characterized by a sudden expansion of robot development in other areas of life.

This is how they appear: robots for the household, robots used for therapeutic purposes, robots for the care of the elderly and infirm, robots for assisting with surgical procedures, robots for putting out fires, robots in the entertainment industry… Some of them have a humanoid shape. Robotics in other areas outside of the industry is often called service robotics, while if the robots have a human appearance, they are called human

The next great progress in the development of robotics was made possible by the emergence of new technologies for the implementation of control systems – microcomputers, which significantly increased the ability of robots to, in addition to other things, process various sensor information in real-time, on the basis of which they make decisions about the next action to be taken, should be performed, and in this way, they perform tasks with a reduced degree of determinism.

It is realistic to expect that this trend will continue, especially due to the development of robotics that is not industrial and where adequate interaction with the environment based on sensor information is a basic prerequisite for the successful operation of robots.

Therefore, it can be expected that industrial robots will have an increased degree of independent action in the future, which will have a very significant impact on production in the future.