From high-rise buildings and industrial plants to bridges and commercial warehouses, steel remains the backbone of modern construction. But not all steel is created equal — especially when it comes to fabrication.

The strength, durability, and performance of a finished structure often depend on choosing the right steel fabrication materials from the start.

At Boardman Inc., we’ve been delivering high-performance metal fabrication solutions for decades. In this post, we’re diving into the most common and critical steel fabrication materials used in the construction industry, and why material selection plays such a vital role in the success of a project.

Why Steel Is a Go-To Material in Construction

Steel offers a rare combination of strength, versatility, and workability. Its ability to withstand extreme loads, resist corrosion (in the right alloys), and support architectural flexibility makes it a foundational material in commercial and industrial construction.

But depending on the application — from framing and supports to tanks and pressure vessels — different types of steel serve different purposes. Selecting the proper steel fabrication materials can mean the difference between a safe, cost-effective structure and a project plagued by delays and failures.

Common Steel Fabrication Materials in Construction

1. Carbon Steel

Carbon steel is the most widely used steel in construction projects. It offers high strength, affordability, and excellent weldability. Low-carbon steel is typically used for structural framing and reinforcements, while medium- and high-carbon steels are used where additional hardness or strength is required.

Use Cases:

- Beams and columns

- Structural supports

- Piping and tanks

- Industrial enclosures

2. Stainless Steel

When corrosion resistance is a concern — especially in buildings exposed to moisture, chemicals, or outdoor environments — stainless steel is a top choice. Its chromium content forms a passive layer that resists rust, making it ideal for both structural and aesthetic purposes.

Use Cases:

- Architectural features

- Food-grade environments

- Handrails and cladding

- Industrial tanks and process equipment

3. Alloy Steel

Alloy steel includes elements like nickel, chromium, or molybdenum to enhance properties such as strength, toughness, and wear resistance. It’s especially valuable in construction projects where high stress or extreme environments are expected. One specialized subset of this category is tool steel, which is engineered for cutting, shaping, and forming other materials — making it indispensable in the fabrication of molds, dies, and high-impact tools.

Use Cases:

- Load-bearing structures

- Machinery components

- High-pressure vessels

- Infrastructure in extreme temperatures

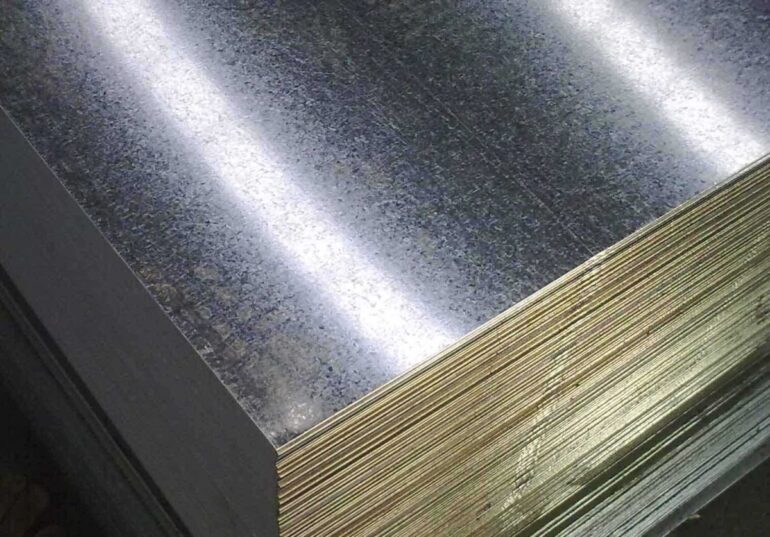

4. Galvanized Steel

Galvanized steel is carbon steel coated with a layer of zinc, protecting it from rust and corrosion. It’s commonly used in outdoor or humid environments and offers a longer life span without frequent maintenance.

Use Cases:

- Roofing and siding

- HVAC ductwork

- Agricultural buildings

- Parking structures

5. Rebar (Reinforcing Steel)

While not a fabrication material in the traditional sense, rebar is vital in concrete construction. It adds tensile strength to concrete, which is naturally strong in compression but weak in tension.

Use Cases:

- Foundations

- Bridges and overpasses

- High-rise building cores

- Retaining walls

Choosing the Right Steel Fabrication Material

Material selection isn’t just about performance — it’s also about budget, ease of fabrication, and compliance with construction codes. At Boardman Inc., we work closely with contractors, engineers, and project managers to recommend the most appropriate steel fabrication materials based on:

- Load and stress requirements

- Environmental exposure (corrosion, moisture, chemicals)

- Thermal conditions

- Fabrication method (cutting, bending, welding, etc.)

- Regulatory standards (ASTM, AISC, ASME)

With the right combination of materials and fabrication expertise, projects not only meet performance requirements but also stay on schedule and within budget.

The Boardman Inc. Advantage

With a legacy of excellence in industrial metal fabrication, Boardman Inc. has built thousands of custom steel components for the construction industry — from structural frames to pressure vessels and everything in between.

What sets us apart:

- Full-service fabrication capabilities (cutting, rolling, welding, assembly)

- Experience with carbon, stainless, and alloy steels

- Skilled tradesmen and certified welders

- Commitment to quality, safety, and precision

- Project management support from design to delivery

Final Thoughts

Selecting the right steel fabrication materials is one of the most important decisions in any construction project. It impacts not only the structural integrity of the final product but also long-term maintenance, safety, and compliance. Whether you’re building a skyscraper, retrofitting an industrial plant, or designing an infrastructure project, partnering with an experienced fabrication company makes all the difference.

Need help sourcing and fabricating top-quality steel components?

Reach out to Boardman Inc. — your trusted partner in heavy-duty steel fabrication.