When you’re planning a project that requires custom metal fabrication, one of the first questions that often comes up is: “How much is this going to cost?” While the price tag can vary significantly from project to project, understanding the key cost drivers can help you make smarter decisions—and avoid surprises down the line.

At Brandywine Valley Fabricators, we know that every project is unique. Whether you're building architectural steel structures, food-grade stainless enclosures, or precision-cut machine components, the final cost depends on a variety of interconnected factors. Here’s a breakdown of what truly impacts the price of a custom metal fabrication job.

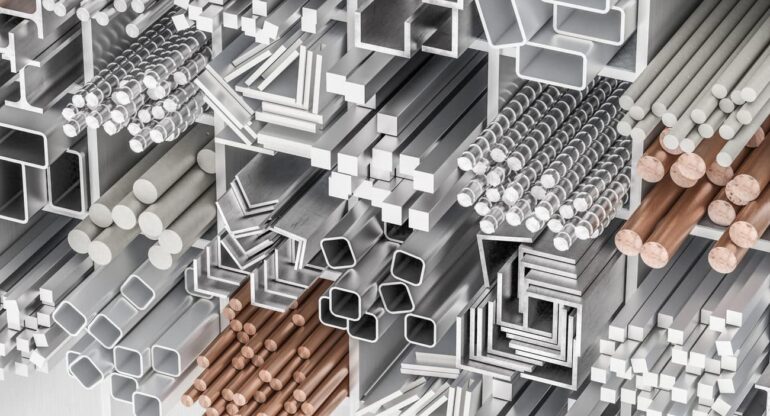

1. Material Selection

Not all metals are created equal. The type, grade, and thickness of material you choose has a direct effect on both material costs and how easy it is to work with. For example:

- Stainless steel is more expensive than mild steel but offers superior corrosion resistance.

- Aluminum is lightweight and corrosion-resistant but may require specialized welding techniques.

- Exotic metals like titanium or Inconel can significantly raise the price due to material cost and machining complexity.

Even small changes in thickness or finish can affect the fabrication process—and the bottom line.

2. Complexity of Design

The more intricate the design, the more time, labor, and precision tools are required to bring it to life. Features like tight tolerances, curved surfaces, or multi-part assemblies often demand advanced fabrication techniques such as:

- CNC cutting or laser precision

- TIG or MIG welding

- Press brake bending

- Machining or milling operations

If your project requires multiple fabrication processes, expect that complexity to show up in your final quote.

3. Volume and Repeatability

Custom doesn’t always mean one-off. But whether you’re fabricating a prototype or ordering a large production run, quantity plays a role in pricing. One-time projects typically have higher per-unit costs due to setup time, tooling, and programming. On the other hand, larger batches may benefit from:

- Bulk material discounts

- Process efficiencies

- Reduced setup time per unit

Brandywine Valley Fabricators can help you optimize your design for manufacturability and scale when needed.

4. Finishing Requirements

If your custom part needs finishing—like powder coating, polishing, anodizing, or sandblasting—these steps add to the total cost. Powder coating in particular is a popular choice because it’s durable, weather-resistant, and available in a wide range of colors. However, it requires surface prep, curing, and skilled application.

Other finishing services like passivation (for stainless steel) or deburring may also be required depending on the function and industry standards.

5. Lead Time

Rush jobs typically cost more. If you need your project completed in days rather than weeks, fabricators must often rearrange production schedules, pay overtime, or expedite material shipping—all of which come at a premium.

Planning ahead can help keep your custom metal fabrication project on time and on budget.

6. Certifications and Compliance

Certain industries—like aerospace, medical, and food service—require strict compliance with safety and material standards. If your project demands certifications like AWS welding standards, ISO 9001, or food-grade sanitation compliance, those requirements can influence both process and cost.

At Brandywine Valley Fabricators, our team is trained to handle high-spec work across various industries with documented quality control systems in place.

Final Thoughts: Transparency = Trust

When you're pricing a custom metal fabrication project, the best way to get an accurate estimate is to work with a partner who communicates clearly and listens to your goals. At Brandywine Valley Fabricators, we take pride in delivering high-quality fabrication with upfront, transparent pricing and expert recommendations to help you stay within scope.

Whether you’re just exploring a new idea or preparing for full-scale production, our team is here to guide you through the custom fabrication process—from initial concept to finished product.

Need a quote or design consultation? Reach out to Brandywine Valley Fabricators today and discover how we can bring your custom metal project to life—on time, and on budget.